I've had a few threads with scattered questions so I figured I'd do a project thread. Started with a matte finish '05 RGT42DXFX with some decent dings and the matte was polished in some places and just generally looked like crap. But the hardware is all good, has a Duncan Vintage Blues set ('59 bridge and neck), and I'm ready for another project. Maple/walnut 5 piece neck, mahogany wings, fixed bridge, etc. etc.. So on I went.

Stripping sucked! The black came off very easy but the polyester sealer was so hard and thick that it took me days of sanding to get to bare wood. Inside the horns where I couldn't get my R/O took me about 7 hours alone. See how thick it is where the chips are?

But alas, it's done and ready for finish. And an added bonus was that the sealer was so thick that as I got it down to bare wood, all the dings were gone. Woohoo!! I've never used a wipe/rub on finish and wanted this to have a satin clear look. So after some research and help from you fellers, decided on using Tru-oil. Not filling the grain because I want the texture of the wood to still be visible. Just sanded everything up to 320 and went at it. Used cheese cloth to apply.

Ready to coat.

1st coat on.

All coats done. 3 coats total, 1st rubbed in and very thin, then 2 medium even coats.

Then after a few hours, I buffed with 0000 steel wool to dull it to satin. Noticed that the bottom edge and inside the horns was really dull, no shine at all. The end grain of the mahogany sucked up all the finish. Well, now they're filled and it'll take more coats and shine. It worked. One medium+ coat and they were good to buff again after about 8 hours to harden.

Here's the finished wood.

And inside with less glare.

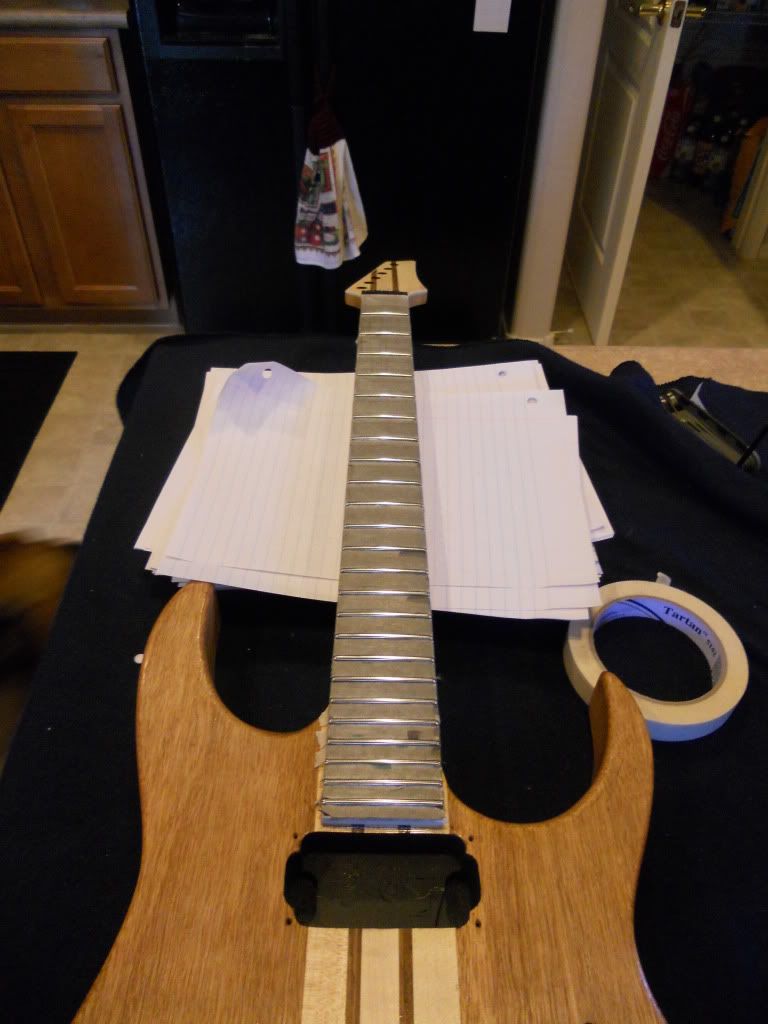

So, now a quick fret level/crown/polish, install hardware, and wire it up. Putting in a Duncan Custom/'59 combo.

More to come..

And for anyone interested, here's a full photo array of the progress.. http://s237.photobucket.com/albums/ff246/warlok1469/Axes/RGT project/

Stripping sucked! The black came off very easy but the polyester sealer was so hard and thick that it took me days of sanding to get to bare wood. Inside the horns where I couldn't get my R/O took me about 7 hours alone. See how thick it is where the chips are?

But alas, it's done and ready for finish. And an added bonus was that the sealer was so thick that as I got it down to bare wood, all the dings were gone. Woohoo!! I've never used a wipe/rub on finish and wanted this to have a satin clear look. So after some research and help from you fellers, decided on using Tru-oil. Not filling the grain because I want the texture of the wood to still be visible. Just sanded everything up to 320 and went at it. Used cheese cloth to apply.

Ready to coat.

1st coat on.

All coats done. 3 coats total, 1st rubbed in and very thin, then 2 medium even coats.

Then after a few hours, I buffed with 0000 steel wool to dull it to satin. Noticed that the bottom edge and inside the horns was really dull, no shine at all. The end grain of the mahogany sucked up all the finish. Well, now they're filled and it'll take more coats and shine. It worked. One medium+ coat and they were good to buff again after about 8 hours to harden.

Here's the finished wood.

And inside with less glare.

So, now a quick fret level/crown/polish, install hardware, and wire it up. Putting in a Duncan Custom/'59 combo.

More to come..

And for anyone interested, here's a full photo array of the progress.. http://s237.photobucket.com/albums/ff246/warlok1469/Axes/RGT project/

Looks great put together. Thanks!

Looks great put together. Thanks!

Comment