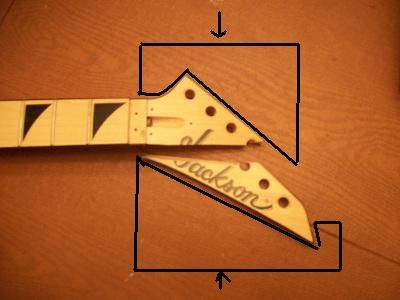

At my local guitar shop there is a trans blue DK2M that is on a horizontal hanger that's right in view when you walk in. Yesterday I noticed the DK2M wasn't there and another guitar was in it's place. I assumed it sold, but when I asked about it I got a long 'Well....' and I knew something bad happened. Someone came in and played with it for a bit, put it back up and didn't angle it back correctly. So when they walked away, it fell, straight on the headstock. The body came out almost unscathed with only one smaller sized ding. However, the neck did not fare so well. He was going to throw it away, and it made the guitar parts hoarder in me want to scream, so I took it.

Announcement

Collapse

No announcement yet.

Is it salvageable?

Collapse

X

-

That's a pretty clean break like toejam said. Dowels or biscuits and wood glue should fix that up ok, clamping it will be a challenge though.It's all about the blues-rock chatter.

Originally posted by RD...so now I have this massive empty house with my Harley, Guns, Guitar and nothing else...

Comment

-

yep just Titebond and clamps would do it.. I'd make a jig out of pine for a clamp to hold onto

Comment

-

Your biggest challenge will be to keep it from sliding as it's clamped. dowels or biscuits can help, but you'll need to make some kind of jig (lined with wax paper to keep the part from sticking to the jig) to hold it all in place while it's clamped.

Comment

-

Yeah, clamping that correctly is going to be the most difficult thing. I wouldn't even dowel that, you have too many weird angles to line that up properly. Biscuits could work, but since that looks like a clean break with the grain, glue is all that's really necessary. If you can clamp it properly, wood glue is all you need.

If you can't do it, or don't feel comfortable, you can probably find a cabinet maker or some other wood shop that could easily repair that for cheap.Last edited by xenophobe; 10-19-2012, 01:11 PM.The 2nd Amendment: America's Original Homeland Defense.

Comment

-

Off the top of my head (and yeah, killing some time at work this afternoon)…..You could go to Lowe’s or Home Depot and buy a little melamine shelf that you’ll use as the base of your jig. Put the neck/headstock face down on the base, and screw a piece of mdf cut in a simiar shape to caul #1 to the base; this part will help keep the neck from shooting back as you clamp cauls 3 and 4 together. You could also put a bolt with a washer in the low E string tuner hold to also hold it in place. Dry fit it together and clamp the triangular cauls together to see how it will go together. If your clamps aren't big enough to span the width, you can cut the top portion of caul 3 like a stair-step (like I did in the headstock gluing pic below). The most important part is to make sure that you’re getting enough clamping pressure without having the neck be squeezed backwards. You can also put some strapping tape over the back of the headstock to help hold it in place while you apply clamping pressure (assuming you’re not doweling). The last bit that I'd want to figure out before hand is how you're going to handle glue squeezeout; generally, you clean it up with a damp rag, but if the headstock is clamped face down, you may not be able to get to the squeezeout on the face in time. The other option is to clamp it with the logo facing up, and just position the neck so that the headstock can lay perfectly flat on your clamping board.

Attached Files

Attached Files

Comment

-

-

Thanks for the detailed response sully! From that picture it looks like I might have to spend more than the neck is worth to buy enough clamps to clamp this sucker down

But seriously, I'm glad it can be used. I was thinking using something like dowels to reinforce the headstock would be required because of the string tension. Is the glue really strong enough to hold on its own? Is there a specific type of glue I should get?

Comment

-

Typically the glued joint (if done correctly) is stronger than the actual wood. That's why they do scarf joints, as the point where the headstock and neck meet is a weak area prone to breakage, so the scarf joint is essentially a precision pre-break, so the bonded joint is actually stronger than the wood originally was.

Why the hell don't they just make the entire neck out of wood glue then? My Gear: Stoneman SG-1, Hufschmid Tantalum H6, ESP KH-6, Sully #8 JCF One-Off, Templar GuitarWorks Relic Prototype, James Hetfield Tribal Hunt KL Explorer, Coobeetsa CCG-10-DX PRO Eagle, Schecter Hellraiser C-1 Hybrid, Daly Heiro Custom, Gibson Les Paul Custom, Gibson SG Menace, Peavey Vypyr 60 Tube

My Gear: Stoneman SG-1, Hufschmid Tantalum H6, ESP KH-6, Sully #8 JCF One-Off, Templar GuitarWorks Relic Prototype, James Hetfield Tribal Hunt KL Explorer, Coobeetsa CCG-10-DX PRO Eagle, Schecter Hellraiser C-1 Hybrid, Daly Heiro Custom, Gibson Les Paul Custom, Gibson SG Menace, Peavey Vypyr 60 Tube

"You are dog shit in my shoe." -Newc

Comment

-

Honestly, I think you'd be surprised. The clamps that I used in the pic would work great for you, and are about $7 a piece, and I don't think you'd need more than three, really. The dowels, IMO, would help mostly with keeping things aligned, although it'd add a little structural help. And as far as glue goes, plain ol' titebond I (not II or III) is cheap.Originally posted by decadence5423 View PostThanks for the detailed response sully! From that picture it looks like I might have to spend more than the neck is worth to buy enough clamps to clamp this sucker down But seriously, I'm glad it can be used. I was thinking using something like dowels to reinforce the headstock would be required because of the string tension. Is the glue really strong enough to hold on its own? Is there a specific type of glue I should get?

But seriously, I'm glad it can be used. I was thinking using something like dowels to reinforce the headstock would be required because of the string tension. Is the glue really strong enough to hold on its own? Is there a specific type of glue I should get?

As far as the reason scarf joints are used, it's really twofold; the first reason is because it's more efficient and less expensive. The structural benefit, however, is vast. If you imagine the grain running down a neck, it's very long at the fretted portion, and very short at the neck joint and headstock. I drew these really fast to kinda illustrate the grain thing:The first image shows how short the grain gets with a 1 piece neck. So you see how short the grain is in the headstock and now it makes sense why Gibson headstocks will snap if the cat farts hard enough at it. The second image shows how the grain is oriented with a scarf joint; it's longer and as a result, stronger. That's not to say that you can't snap a scarfed headstock (clearly!), but you don't get the same kind of breaks you do with the other method.

1pcneck.jpgscarf.jpg

Comment

-

I was thinking of a jig a bit different (and I think easier) than sully's. I saw a while ago (maybe from Budman's model 6???) where for a fretboard they used a few small metal pins to mock up, remove, and realign again when glued in place. Like this, hope it makes sense:

-Get 2 or 3 small pins (cut 3/16" of a finish nail for the pins), As straight as possible, nail them 1/2 way into one side. Line up (dry) the other side perfectly where it needs to go. Tap the pieces together. Pull them back apart. Now you have alignment pins and holes installed.

-I think the jig should be like this. Use just a soft pine piece of 2X8 (or 2x10 etc..) and cut with a jigsaw or whatever you can make good cuts with.. It should hold good with 2 clamps on the sides IMO.

[IMG] [/IMG]

[/IMG]

Make the jig, cover jig and clamps with wax paper, glue both pieces, align pins and push together, install jig and clamps, walk away, drink beer, drink more beer, stoip thinking about going and seeing if it's good yet, HEY!! I said get away from it!! Drink more beer, sleep wake up, cure hangover, now you can go take clamps and jig off. Repair finish as necessary and build something with it that rocks!!! And finally, play the holy hell out of it!!Every man dies... Not every man really lives!!

Comment

Comment